Have the tires worn thin on your 130-year-old ordinary bicycle? Does your pedal car need new shoes? Vintage tricycle got a flat? Here is one way to replace those old solid-rubber tires.

This is the first time I’ve offered a how-to article. In researching this very old process on the Web, I found only two detailed sources: they were from

Dave Toppin and

Rideable Bicycle Replicas. My process is a combination of both those I found, revised through trial and error. If you’re seriously considering replacing solid-rubber tires, you would do well also read the processes described by Mr. Toppin and RBR.

The solid-rubber tire material, which is almost solid except for a small-diameter hole through the center just big enough to slide in a 1/8-inch-diameter steel wire, is cut to length slightly oversize, and the wire is threaded through and pulled taught around the wheel while the ends of the rubber tire are held apart so that the wire can be brazed together.

- Tire material from Holmes Wheel Shop.

- PVC tubing cutter to achieve accurate, square cuts through the tire material.

- 1/8” diameter (9 gauge) solid, steel wire from your local hardware or home-improvement store.

- Fine sandpaper for removing corrosion-preventative coating from the wire where it will be brazed.

- Silicone lubricant to help get the wire threaded into the rubber tire material.

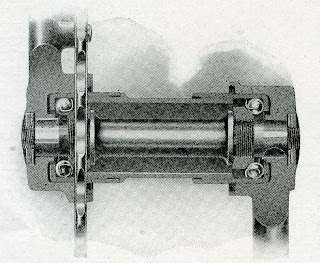

- Fabricated tool to keep ends of rubber tire material apart when tensioning the wire and brazing together its ends. See photos to get an idea of the one I made out of 1.5” steel tube and a couple of thick washers with slots cut in them. (The slots in the washers are necessary to allow the tool to be removed once you're done!)

- Cable clamps to allow you to form a loop in each end of the wire so that it can be attached to a sturdy rack or other fixture and the come-along.

- Come-along (hand winch) or other device to tension the wire.

- Sturdy rack or other fixture to hook come-along to for tensioning wire. This may have to be able to withstand up to 150 or 200 lbs of pulling force depending on the size of the wheel you are re-tiring and the thickness of the tire. (Less pulling force may be sufficient for larger wheels). I used an over-built steel work bench. A towing ball on the back of your truck would work well for one end of your fixture.

- Two pair of needle-nose Vice Grip pliers to clamp tensioned wire while excess wire is cut away and ends are brazed together.

- Die grinder with cut-off wheel and rotary-file bit for cutting away excess wire and profiling the brazed joint so the tire material will close over the joint.

- Oxy-acetylene torch kit and brazing rod.

- Small piece of scrap sheet metal for use as a heat shield to protect the wheel when brazing.

- Wet rag to quench the brazed joint once the job is done.

Procedure

Cut tire material oversize. Add an extra inch of length for each 10 inches of wheel diameter. For instance, if you have a 10-inch wheel, the appropriate length of tire material will be enough to go around and overlap 1 inch. If re-tiring a 50-inch wheel on an ordinary bicycle, the overlap will be 5 inches. Ensure the cut ends are smooth and square. Use a PVC tubing cutter and practice. For small diameter wheels, you might try to put a very slight bevel in the cut so that the length of tire along the wheel is very slightly less than the length along the outer diameter.

Cut wire to size and prepare the wire to be brazed. The length of wire necessary will be enough to go around the wheel, between the legs of your sturdy rack or other fixture, plus enough for a loop at each end. Cut the wire to size, lay it over your cut-to-size piece of tire material, and mark the approximate area along its length where the wire will protrude from the ends of the rubber. This is where the brazing will occur. Use fine sandpaper to remove the corrosion-preventative coating from the wire over an area about 5 inches either side of where you figure you’ll be brazing together the two ends. You can use a permanent marker to identify the ends of the area that you have prepared.

Install the wire. Use a file or die grinder to round off one end of the wire so you can feed it into the tire material. Depending on the length of the material, you might have to use silicone lube to get it through. The spray silicone lube will run down inside the tire and so might help with particularly large or stubborn cases. Feed the wire through the tool so that the two protruding sections of the wire cross one another. Wrap one end of the wire around a leg of your sturdy rack or other fixture, and secure it with one or two cable clamps. Put a loop in the other end that is big enough to put the come-along hook through, and secure it also with one or two cable clamps.

Tension the wire. Hook up the come-along, and fit the wheel into the tire. The wheel will have to be held in place with tape or light spring clamps until there is enough tension on the wire to compress the tire to hold the wheel. Consider laying towels or other soft material under the wheel to catch it in case there is a sudden loss of tension (wire breaks, fixture breaks, etc.). Crank the come-along until the tire material is snug against the wheel, then give it a little more additional tension to ensure that the ends will close over the gap and touch each other once the tool is removed. It should not need a lot more tension to ensure the joint closes when you are finished.

Prepare for brazing. Clamp the wire with needle-nose Vice Grip pliers at the point closest to where the wire emerges from the tire. Remove the come-along. Cut the wire with the die grinder so that there is about 1 inch of overlap. Bend the ends so that they touch along the length of their overlap. Clean the ends well, removing any silicone or other oils or dirt that might contaminate the brazed joint. Slip a suitably-sized piece of scrap sheet metal under the wire joint to act as a heat shield.

Braze ends. Use a small, hot, oxy-acetylene flame to braze together the two ends of the wire. Immediately quench the joint with a wet rag to prevent the hot wire from burning the rubber tire.

Finish the joint. Use a die grinder with a rotary-file bit to bevel the brazed joint along its length so that it is not substantially wider than the rest of the length of wire or the hole in the tire material. Use needle-nose pliers to twist the joint slightly so that it aligns straight with the rest of the wire. Clean out the grinder chips and any other debris, and remove the heat shield. Remove the tool by pulling it or levering it out with screwdrivers.

The compressed tire material should close over the brazed joint, with maybe a little help from you working the rubber to help it slip along the wheel and over the joint.

Roll away!

I hope that this post is helpful. This process worked for me, and I hope it'll work for you, too. As always, work safely. Fire and stored mechanical energy can be dangerous, so please try to anticipate what could go wrong before it does. I cannot be liable for things going wrong on your project.

If nothing else, my procedure sheds some light on how the Racycle Crank can turn the seemingly simple into an involved exercise. It might get simpler with practice.